This site is curently dormant and not frequently updated right now.

Thanks for your patience while I update.

Latest additions

- Overlays for Akaï Midi Mix (soon)

- Overlays for Behringer BCR32 (to follow)

Be informed when new overlays are available:

How can I customize Midipoti’s overlays ?

If you are not used to graphic software:

-

- quick and easy

- editable and re-useable

- does not increase the price due to expensive online customizer, and is free for all.

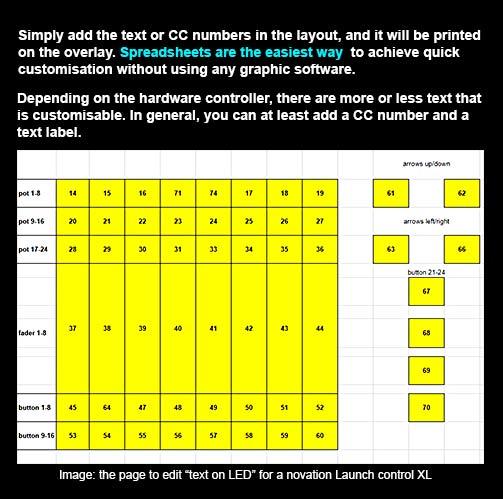

So, it is simply done the best way: with a simple spreadsheet (check ressource page).

The process is simple:

- Access the spreadsheet coresponding to your controller,

- Do not change/add/remove cells/rows/columns, or it will not work.

- Add texts or numbers where you want them to appear

- Export as .csv and send it to us after your order.

- Done ! You will receive a preview before final production and delivery.

What about future modifications of the my design ?

We keep track of your design and if the modifications concern only a few elements, it takes less time to do and so is cheaper to re-print.

That way you can make your overlay evolve with your workflow without spending fortunes.

How many overlays do I need ?

Users generally have one main overlay that they design carefully so it is exactly what they need, and another which is less specific and which can be used for any purpose.

You may also add an overlay for your favorite synth or the main parameters of a mastering chain.

So that’s about 3 types of overlays:

- Permanent (eg. studio controls, Daw shortcuts (reaper), hardware or DSP based equipment))

- Generic (fits all, no particular design, but well labelled midi CC numbers of your main template.

- Another generic for future usage, or purpose-specific (eg, synth editor, mastering workflow, live concert).

How many Midi CC templates do I need to program on my midi controller ?

- I personnally do everything with 1 midi CC template.

- Changing the overlay is enough to adapt many situations. The midi CCs numbers never change.

- Having several templates would be for those with specific audio gear whit fixed, not editable, midi CC setups. otherwise, most plugins and DAWs are configurable.

- So far, my favorite midi controller is the novation launch control because it feels like real potentiometers and midi CC numbers can be backlit by the colored led. The way i use it does not need encoders with position recalls (once i recorded the midi CCs, I just need to edit them in the DAW if it needs improvements).

“Overlays are a secret weapon for peak performance”

What exactly are overlays and what do they do ?

Overlays transform your screenless controllers into intuitive instruments that are immensly better than staring at a screen and switching windows for hours on end. They’re customizable too: once printed, they turbocharge your workflow, offering professional and sleek aesthetic with easily readable text, MIDI CC info, and smart section groupings.

They are for MIDI devices and not HID devices like streamdecks and keyboard shortcuts: so they do not need the target software to be “focus” or open. They are available 100% of the time whatever is currently shown on the computer screen.

For those of us with a set studio setup, overlays become our trusty sidekick.

- They grant us instant access to our most-used functions without the constant screen-checking or window-switching.

- Thanks to MIDI control, we can breeze through our DAW without ever pausing to recall which CC number does what.

- A quality overlay isn’t just for one plugin—it’s tailored to your unique workflow, grouping controls into modules that adapt to any project.

- Some controls are labeled, while others are left open for customization, ensuring seamless integration into our creative process.

- Picture your essential clippers, equalizers and maximizers seamlessly integrated with clear labeling, organized sections, and highlighted parameters. This seamless integration allows you to confidently manipulate parameters, without the necessity of opening any plugin window.

- A clear overlay provides immediate access to critical parameters without the need to navigate multiple plugin windows.

Live gigs can be nerve-wracking, especially if you’re fumbling with controls onstage. But overlays change the game.

- With only the essential controls at your fingertips—mixer levels, filters, EQs, and FX amounts—you can focus on the music, not the gear.

- Each overlay should keep similar controls in familiar places, so even if your synth changes with every song, you’ll always know where to find that filter cutoff or FX dial.

- No more mid-performance panic over forgetting which knob does what.

For synth enthusiasts, overlays are your ticket to effortlessly browsing presets and quickly editing parameters like oscillators’ tuning, ADSR, and filters. Overlays are the best to control modulators such as LFOs, because you can modify rate and speed at the same time.

- Imagine having the tactile feel of hardware synths right at your fingertips, with overlays that mirror the look and feel of your favorite instruments.

- And while squeezing every parameter onto a single overlay might not be feasible, experienced overlay makers ensure that every control serves a purpose, drawing on years of synth plugin expertise.

Overlays are true enhancer for music making.

- They simplify our workflows, enhance our creativity, and offer a tangible connection to our digital tools.

- With their affordability and adaptability, they’re a no-brainer investment for any music producer.

- It is your unique design, and it is a joy to use.

What is a flip-board compared to an overlay ?

Overlays generally have one useable side, because the controller is not symetric.

Flip-boards give you 2 overlays in one. You can use both A and B sides. The A-side contains texts and precise designs, while the B-side provides light colors and no text, for your own customization. It is not always possible to make a flip-board because many controllers are not symetrical. However, it is often possible to cut an overlay in 2 parts in order to create a part that is symetric and can be flipped.